Call Us: 440-946-5300

Precision 15-5PH Stainless Steel Investment Castings

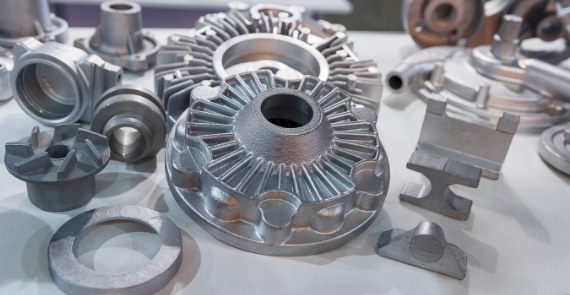

For high-quality, corrosion-resistant investment castings, 15-5PH stainless steel is ideal. Bescast utilizes our decades of precision investment casting experience to create 15-5PH stainless steel products for dozens of applications. From concept to production, we provide design and engineering support throughout your product life cycle. Get the very best in 15-5PH stainless steel castings with Bescast.

15-5 Stainless Steel Properties

Among the family of stainless alloys, 15-5 stainless steel's properties stand out. 15-5PH stainless steel is notable for its high strength, hardness and superior corrosion resistance. As a precipitation-hardened, martensitic alloy, 15-5PH stainless steel contains chromium, nickel and traces of carbon. Its heat treatment provides better transverse toughness and ductility than 17-4PH stainless steel.

Combined with Bescast's precision investment castings, 15-5PH stainless steel can be formed into hundreds of complex parts, components and tools. Its hardness and strength make it ideal for applications where component wear is a concern. Products made from 15-5PH stainless steel include:

Gears

Driveshafts

Structural Components For Aerospace

Valves

Nuclear Reactor Components

Oil And Gas Components

Frequently Asked Questions About Our 15-5PH Stainless Steel Castings

Working with Bescast on your precision investment castings means working with a premier casting design and engineering solutions provider. Our 15-5PH stainless steel castings use the same high standards as our other stainless steel components. Leverage our decades of experience developing and producing precision components utilizing a variety of materials

What Is 15-5 Stainless' Machinability?

15-5 stainless machinability before heat treatment is similar to 400 series stainless steel. Following heat treatment that hardens the material, its machinability noticeably declines. With precision investment casting, your components are formed into your desired final product and require minimal post-processing, reducing concerns around 15-5 stainless' machinability.

What Certifications Does Bescast Have?

With our commitment to quality, we have gone out of our way to achieve several industry certifications to distinguish ourselves as a leading global manufacturer of 15-5PH stainless steel precision investment castings. Our certifications include:

- ISO 9001:2015

- AS9100 Rev D

- NADCAP

- NDT (Non-Destructive Testing) (Radiography & Penetrant)

- Heat Treat

- Welding

Do You Offer Prototyping Services?

We do. Our full team of designers and engineers can help you at any stage of the part development process. Utilizing ProCAST software with Finite Element Analysis (FEA), we simulate casting processes with high accuracy and aid in the understanding of solidification regarding your 15-5PH stainless steel castings.

Call on Bescast for 15-5PH Stainless Steel Investment Castings

Utilizing more than 75 years of industry experience, engineers from around the globe have relied on Bescast's precision investment castings. Producing components using 15-5PH stainless steel is one of our many core competencies. Using the best in state-of-the-art tools and technology, you can rely on us to develop and produce 15-5PH stainless steel castings that meet your design specifications. Contact us today to learn more about what we can do for you.

CURRENT PRODUCTION

Manufacturing Capacity

• 75,000 ft2 manufacturing facility

• 10,000 ft engineering and customer service

• 200+ full-time employees

Alloys Currently Poured on a Production Basis

Steel

• 15-5PH

• 17-4PH

• 300 Series

• 400 Series

Cobalt

• MM509

• L605

• X40 (S31)

• WI-52

Nickel (vacuum)

• HastX

• IN100

• IN625

• IN713

• IN718

• IN738

• IN792

• MM247

• R77

• R80

• R125

• U500

Quality Certifications

• ISO9001:2015

• AS9100 Rev D

• Nadcap

• Heat Treat

• NDT (Non-Destructive Testing) (Radiography & Penetrant)

• Welding

Approved Supplier To:

• Advanced Atomization Technologies

• Collins Aerospace

• Eaton Corporation

• GE Aviation

• Parker Hannifin

• Pratt Whitney Canada

• Prat Whitney America

• Rolls Royce N.A.

• Siemens Energy

• Solar Turbines

• Woodward